Why is it important for operators to pay attention to air quality?

Read moreAsk for

a quote

If you are interested in any of our services, please contact us for a quote!

You can plan with us

We apply clear and transparent processes from offer to delivery.

Thinking in systems

Since changes to any part of a system affect the system as a whole, the technical solutions to a subtask are considered in the context of the whole system.

Innovation

We are constantly evolving and looking for new, environmentally friendly technologies.

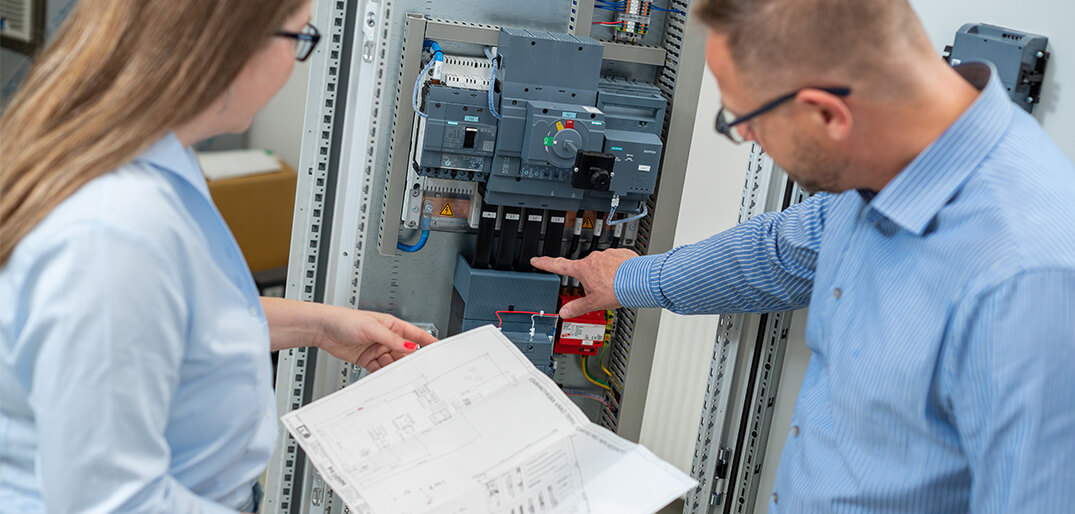

Using today’s technologies, nearly half of the human-intensive work processes can be automated. The main goal of industrial automation is to increase competitiveness, efficiency and productivity. Automation solutions are always unique and the best choice depends on a number of factors, so there areno ready-made templates. We help our partners to find the most ideal solution from the needs assessment to the commissioning.

After assessing your needs, we help you choose the automation equipment and carry out the electrical design of the system.

We develop DCS, control, PLC and HMI (OP, SCADA) software for your automation system, tailored to your specific needs.

At our Budapest site we pre-assemble and test electrical and pneumatic cabinets.

We assemble and install the electrical and pneumatic automation system at the end user’s site.

Linde Gáz Magyarország Zrt. is one of our key partners. We have been continuously present in the gas industry sinceour company was founded. We are proud of the fact that we have commissioned gas plants for Linde in many countries across the globe and have successfully completed many different projects together.

In 2010, we automated the first cartridge washing system for the company, which included a production tracking system. After the project was completed, production optimisation reduced the three-shift production to two shifts, while the overall productivity of the company stayed the same.

The plant's conveyer belt packaging machine was causing continuous breakdowns in the production process. The machine was optimised by rewriting the PLC and HMI software without any hardware modifications, which significantly increased its uptime to almost 100%.

The IJSFABRIEK STROMBEEK plant has the largest N2O production facility in Europe, which was fully automated by our company. The upgrade has increased production capacity by 50% without increasing the number of operating personnel.

The air monitoring system installed at the plant monitors the concentration of harmful gases during the production process, which gives an alarm if the value is outside the healthy limit. In this way, the customer ensures a safe working environment and also complies with the ITM regulation.

In recent years, we have supplied two large-capacity gas plants to one of the largest Korean multinationals, who are also direct suppliers to LG and Samsung, among others. The investment will enable it to cost-effectively serve increased customer demand.

The task was the automated coordination of the material handling system and the tinning tank, which came from different suppliers. The technology creates harmful fumes and gases, with a risk of burns. Automation increased efficiency and reduced the risk of accidents.

The EU has a drive to increase energy efficiency for large consumers. As a first milestone required by government regulation, we have installed smart meters at the factory consumers, from which we transmit the measured values to the data processor via the network.

If you are interested in any of our services, please contact us for a quote!

Our industry experience.

Why is it important for operators to pay attention to air quality?

Read moreEnergy measurements are now mandatory. We will try to briefly summarise the requirements.

Read moreWhat are the standards to look out for when considering an automation system?

Read more

This website uses cookies to improve your experience while you navigate through the website. Cookies are small data files which are placed on your computer or mobile device when you visit a website or use an online service. For example, cookies enable us to identify and authenticate you and remember your preferences so we can enhance your experience on our websites.In addition, it helps to provide certain functions, to ensure their smooth operation, to maintain the security of our services and support to develop our website.

We'll assume you're ok with this, but you can opt-out if you wish. You can do this using the tabs on the left.

You can view our Privacy Policy for more information about the cookies.

These cookies support to use our website. For example save cookie settings. If you disable this cookie, we will not be able to save your settings, which means that you have to re-enable or disable cookies every time you visit our website.

If you disable this cookie, you will not be able to use third-party cookies.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information. They are absolutely necessary for the site to work, so they cannot be turned off. I accept the use of these cookies by using the site.

You can view our Privacy Policy for more information about the cookies.

This website uses cookies to improve your experience while you navigate through the website.

You can see what cookies we use at the link below settings.