What is industrial automation?

Industrial automation is the process of automating some or all of the tasks that can be done by human hands, using available technologies. This is not limited to robots, but to any machine system capable of performing predefined tasks autonomously.

What are the main benefits of industrial automation?

- Increasing productivity,

- greater competitive advantage,

- quality improvement,

- environmental awareness,

- cost optimisation,

- reducing repetitive processes that require human resources,

- reducing employment risks,

- improving working conditions.

Which areas of industry can be automated?

It’s almost impossible to find an industry where the manufacturing process cannot be automated. There are clear signs that the labour market of the future is moving towards full automation, where automation is combined with artificial intelligence.

Featured clients, references

The process of industrial automation

Automation solutions are always unique and their design depends on many factors, so there are no ready-made templates. Our company is specialised in the implementation of the most optimal automation system after having understood the given production process. The steps are the following:

1. Survey and planning

Based on the technological process and the customer’s requirements, we carry out the necessary calculations and dimensioning, select the electrical and pneumatic equipment. Using the EPLAN target software, we prepare the electrical and pneumatic design documentation according to the standard in Hungarian or English. Our design practice also covers the following special design areas:

- Industrial safety engineering,

- explosion safety engineering,

- airspace analysis.

2. Industrial software development

During the design phase, we support you in the selection of controllers. The HMI (OP, SCADA) software specification (SDS) is prepared in consultation with the customer. The end user operates the equipment via the HMI, so it is important that the concepts meet at this point. Once the specifications have been approved, the coding of the software (HMI, PLC, DCS) begins.

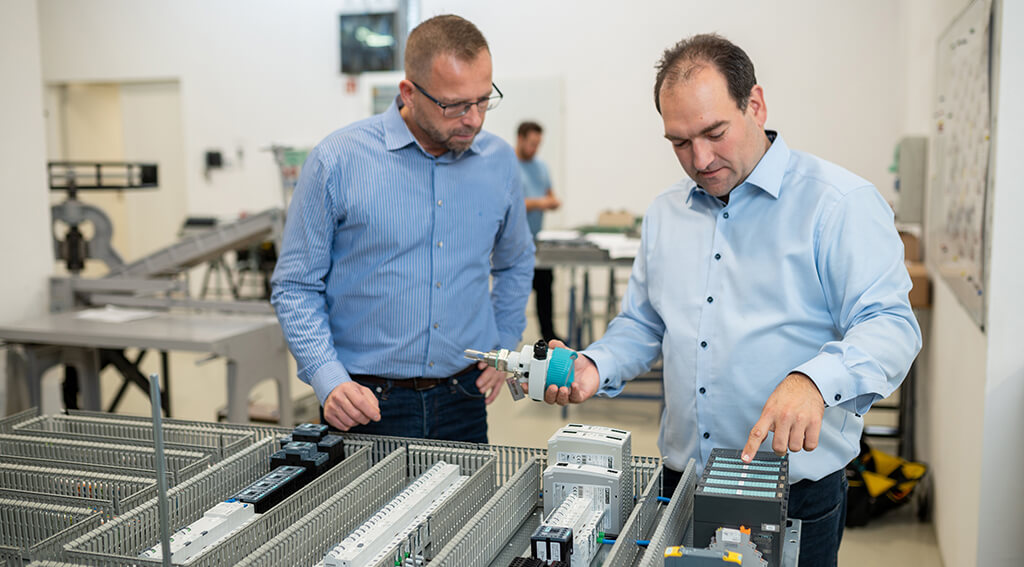

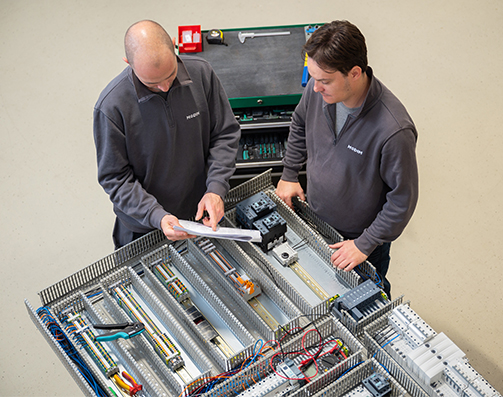

3. Manufacture of electrical and pneumatic control cabinets

Once the electrical plans have been finalised and the equipment has been procured, the preinstallation of the electrical cabinets can begin. The production of custom automation cabinets at our Budapest site is continuously supervised by project engineers, the completed cabinets are tested (FAT), and CE certified.

4. Field construction, commissioning

We deliver our electrical and pneumatic cabinets to the place of use. We carry out the field wiring and instalelectrical connections. We revive the system, test it (SAT/SIT) and deliver it to the customer in commissioned condition for test operation. In addition to the warranty period, we also provide longterm support for the cabinets we install (eg. maintenance, repairs, replacement parts), as required by our customer.

People who help industrial automation

Ferenc is one of the founders and a managing director of our company, he graduated from the Faculty of Electrical Engineering at BME. Over the years, he has gained valuable knowledge in the fields of electrical design, industrial safety engineering and explosion safety engineering, complemented by an extensive knowledge of standards. He strives in his work to meet the highest professional standards, paying attention to detail and successfully completing projects.

Lajos, one of the founders and amanaging director of our company, he graduated from the Faculty of Electrical Engineering at the BME. His main area of expertise is industrial software development, but his qualifications as a registered engineer prove that electrical engineering is not far behind. Innovation is a major part of his life and he is constantly striving for improvement. He sees a special value in good professional relationships that help him in his work and are a cornerstone of the company's success.

Peter, a graduate in electrical engineering from BME, is one of the founders and a managing director of our company. His professional focus is the design of control and manufacturing support software at functional and architectural level. He has experience in the preparation and implementation of major investments, supported by his economics degree. Sustainability and the use of renewable energy sources in the company's activities are important to him.

Ferenc has been head of the construction department since 2015. As a technician with a master's degree, who is constantly expanding his knowledge through professional training, he is ideally suited for this job. He takes great pride in the precision and high quality of his work, to which his team contributes. His experience and skills ensure that every project he is involved in is completed to the highest possible standard.

Péter started his career in our company in 2015, he is a mechanical engineer. Over the past years he has proven to be an outstanding talent in project management. He has successfully combined his expertise with the electrical knowledge required for industrial automation, and he focuses on collaborative thinking during his work. This combination makes him a key project manager in our company, where he has successfully completed a number of projects.

Richard has been part of the team since 2017. Thanks to his degree in electrical engineering, he has the necessary knowledge to deliver successful projects. He has a strong systems approach, which helps him to plan and implement his projects with attention to detail. His good communication skills enable him to manage his team well and to constantly strive for perfect cooperation.

Martin joined our company in 2017 and is now the head of our software development department. With a degree in mechatronics engineering and economics, he has a wide range of professional skills, backed up by his drive for continuous improvement. As an excellent team player, his highly motivated approach and his belief in creative solutions ensure that his projects are implemented exceptionally well.

The cooperation process

Survey, offer

After the initial consultation, we will assess the site, draw up an offer, which is often refined during further consultations.

Design, production

We will learn about the manufacturing process, followed by our work on the electrical design, software developmentand the production of control cabinets.

On-site installation

We deliver the preassembled cabinets. After the on-site assembly and functional tests, we start the trialoperation.

Frequently asked questions

Our colleagues will contact you by e-mail or telephone to arrange an appointment. We will first discuss the job in broad terms by phone or online, followed by an on-site survey and finally the quotation.

There is no charge for the submission of the offer, nor for the consultation and survey relatedto the submission of the offer in Hungary.

Our main profile is the (electrical) control side of industrial automation, but we also work closely with engineering partners with whom we also undertake general engineering.

There is no definite no to this, but very often you can automate your existing production line with the right instrumentation, so in such cases it is essential to have an on-site survey before makinga bid.

In the course of our work, we very often come across unique technology or know-how. In such cases, we sign a confidentiality agreement with the client with strict conditions.

In Hungary, standards are based on voluntary use, except for a few legal references. However, if a manufacturer, including us, considers itself bound by the relevant standards, it is a guarantee that its products are of good quality.

Get a quote now!

If you are interested in any of our services, please contact us for a quote! You can find out more about the details of our services and how we can help you.